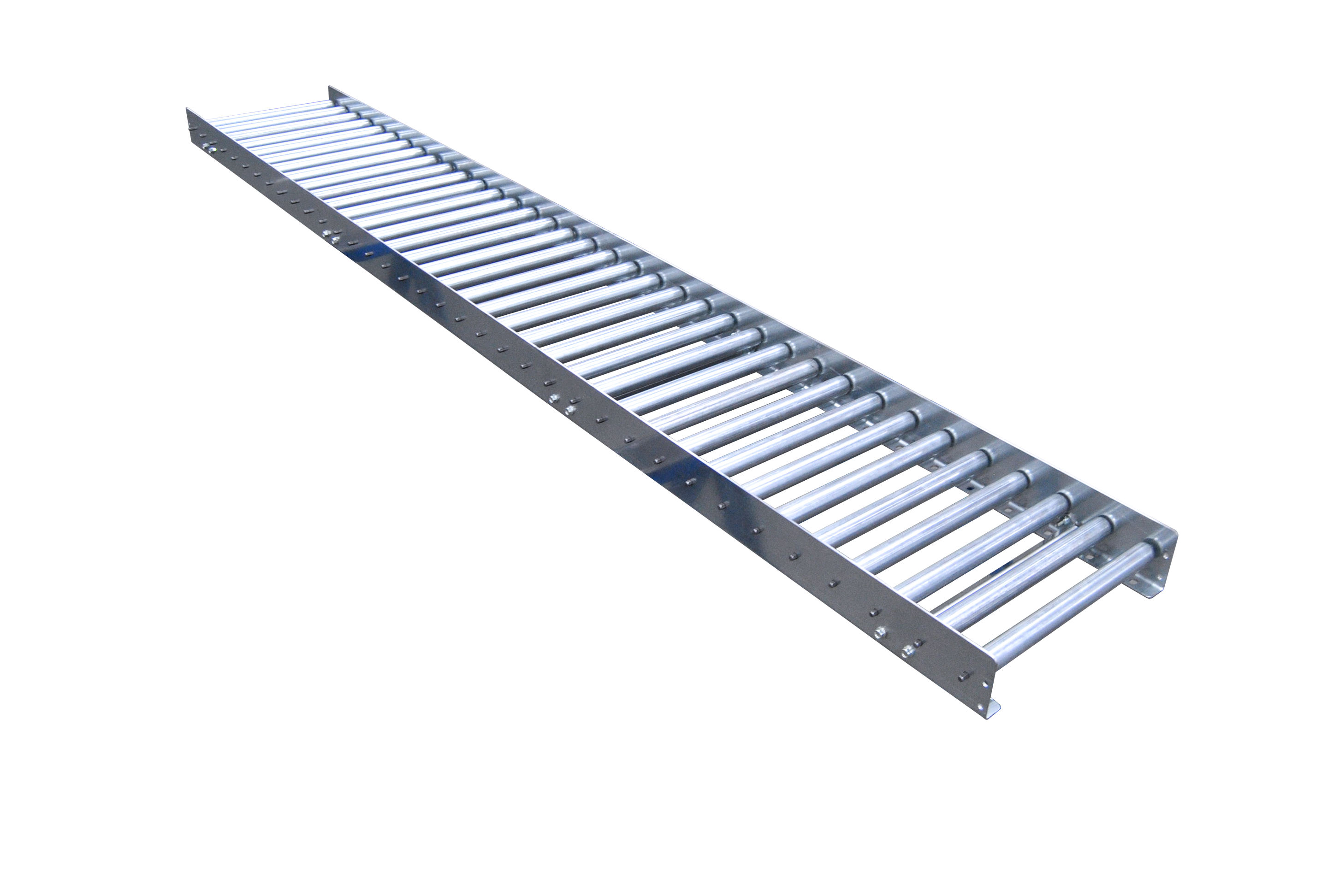

OVERALL LENGTH: 18” to 120”

ROLLER DIAMETER: 1418

BETWEEN FRAME RAILS: 12″ to 27″ (16″ common)

ROLLER CENTERS: 3”

STANDARD SUPPORT HEIGHT: 60″

MAXIMUM SUPPORT SPAN: 84″

CROSS MEMBERS: 1.5″ X 1.5″ X 12 GA, GALV

SUPPORT MATERIAL: Plain Carbon Steel Painted Ral 9005 Jet Black

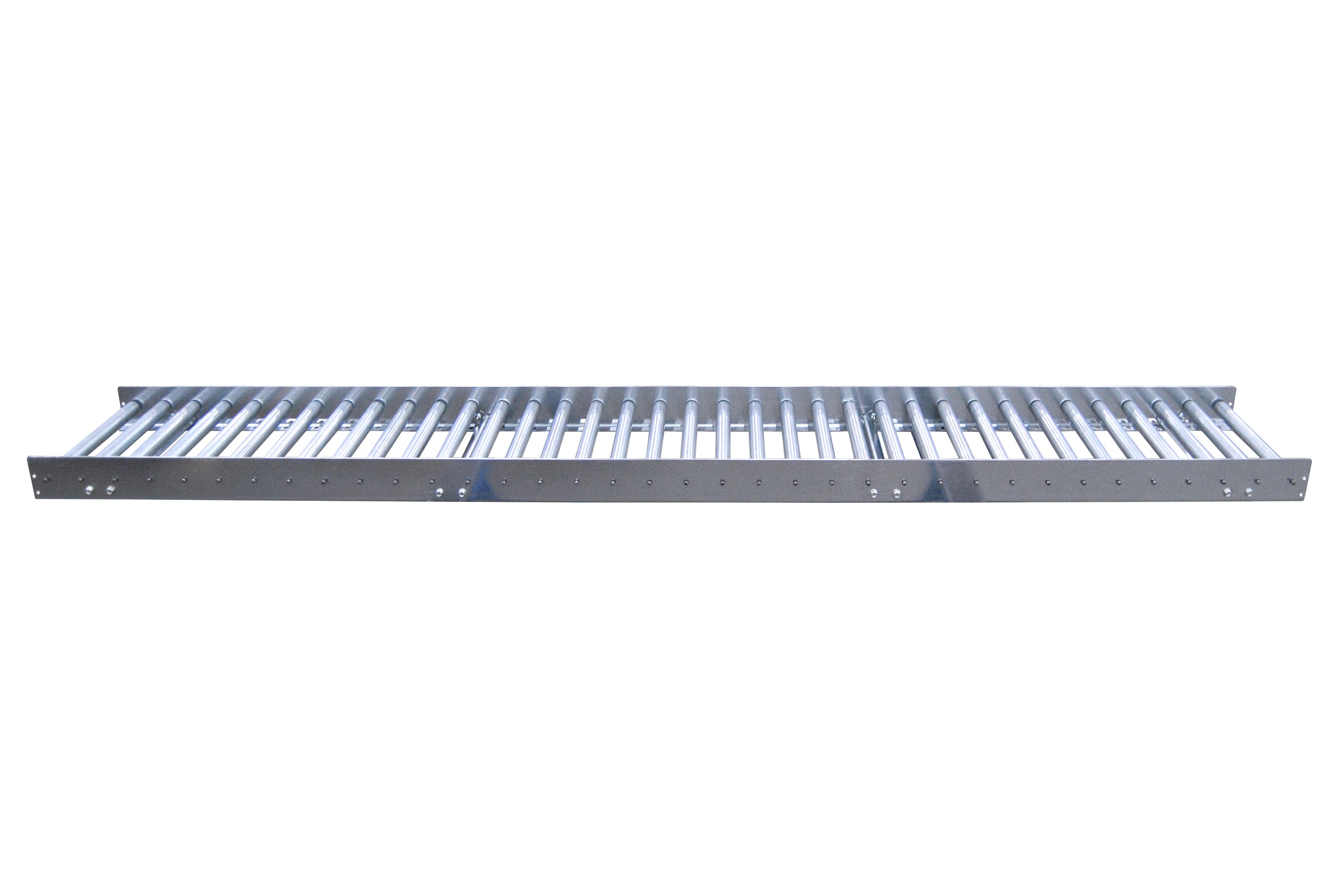

FRAME MATERIAL: Galvanized Steel

SIDE CHANNEL: 4″ X 1.5″ x 10 GA GALV – L Shaped With Rollers Set Low To Create A 1-5/16” Side Rails

Optional Features:

- M-series design does not use butt couplings, we do offer splice plates as an additional feature but are

not required.