Ball Transfers

Rolmaster Conveyors’ Ball Transfers come in three different styles Drop-In, Frame, and Pan. Ball Transfers offer adaptive solutions that facilitate the smooth movement of flat-bottomed loads in various directions, making them ideal for conveyor intersections or the beginning and end of conveyor lines. Whether you need packaging, assembly stations, or are engaged in manual rotation of products, these product enhances workflow and versatility.

Workers will benefit from easy access to all sides of the product, essential for ergonomic assembly, inspection, and testing stations. Drop-In style Ball Transfers can be a quick and easy way to modify your existing gravity conveyor where the product needs to be manually rotated or a manual change in direction is required. With a Drop-In style Ball Transfer, you can remove the rollers in one section of the conveyor and easily create an ergonomic workstation.

Standard Features that apply to all Standard Ball Transfer Conveyor Models:

- Ball Transfer: 1″ dia. zinc plated ball transfer with 1/4-20 UNC stud mount.

- Available Ball Centers (BC): 2, 3, 4, and 6 in

- Staggered and Straight pattern layouts

Below lists “standard” Ball Transfer Conveyors which we manufacture and sell. Rolmaster can accommodate most custom “non-standard” Ball Transfer Conveyor requests.

-

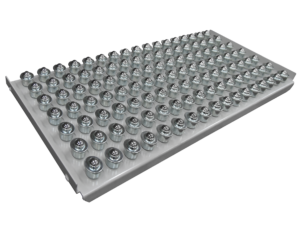

BTD – Ball Transfer Drop-In Style

Designed to be dropped into frames with 3.5” tall channels to create a ball transfer section in an existing Gravity conveyor.

-

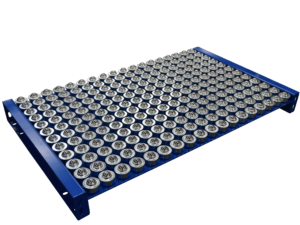

BTF – Ball Transfer Frame Style Conveyor

Designed to use the same frame dimensions as 1.9” diameter rollers to create a level roller to ball surface.

-

BTP – Ball Transfer Pan Style Conveyor

Designed to eliminate the hard edge created by a channel. Preferred in areas where operators lean against the conveyor.