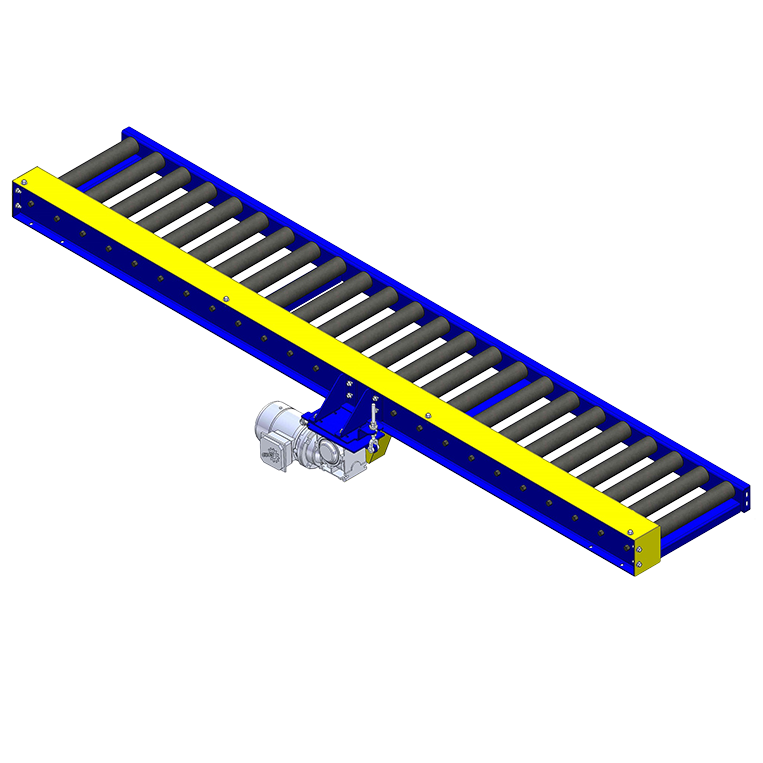

OVERALL LENGTH: 40” to 120”

OVERALL WIDTH: 11” to 75”

OVERALL HEIGHT: 17-3/16”

EFFECTIVE BETWEEN FRAME RAILS: 4-½” to 68-½”

MOTOR OPTIONS:

ELECTRICAL INPUT:

- 575V / 3 Phases / 60HZ

- 230 to 460 V / 3 Phases / 60HZ

- 110 V / 1 Phase / 60HZ

HP: ½, ¾, 1 or 1-½”

MOTOR ORIENTATION OPTIONS:

- Top: Center, Front or Back

- Bottom: Center, Front or Back

Front & Back Orientations are Only Available when Overall Length is more than 60”

ROLLER CENTERS: 4”, 4-½”, 5”, 6”

ROLLER: Round Tube, 2-1/2″ Diameter, 11 Gauge

ROLLER AXLE: 11/16” Hex Axle

SIDE CHANNELS:

- 4” X 1-½” X 3/16”

- 6” X 1-½” X 3/16”

FRAME MATERIAL: Plain Steel

FRAME COUPLING: Butt Couplings

FRAME FINISH: 5017 Traffic Blue

OPTIONAL FINISH: 1021 Safety Yellow – 3001 Signal Red – 7015 Slate Grey – 9005 Jet Black – 9006 Aluminum White

CAPACITY: Varies pending roller centers and BFR. Contact us to review your application.

MODEL STRING: Conveyor Type – Mechanism Type – Roller Model – BFR – Rollers Centers Distance – Overall Length – Frame Type – Finish – End Connections & End Cover Type – RPM/Motor Number

Example: CR-D-2511-18-5-120-F8-5017-CA-100M17 (Chain Roller Conveyor, Drive Mechanism, 2511 Roller, 18” Between Frame Rails Length, 5” Center to Center, 120” Overall Length, Frame8, 5017 Traffic Blue, Sprocket on Front Side/Collar on Back Side & No End Cover, 100 RPM/Motor 17)

Optional Features:

- Knee Braces or Mid Support Holes

- Side Rails (Toe Out Left, Right or Both)

- End Stop (Front, Rear or Both)